NiCr (read as 'nicrome') is the name of my CNC Hot Wire Foam Cutter, an OpenSource/OpenHardware project that I'm making public with this post.

The github repository: https://github.com/JMG1/NiCr

Description:

As the name says, the machine cuts shapes from foam blocks, being the original intention to cut wing cores for lamination and molding.

I've composed a little video about it:

I'm opening this project in exchange of all the good things that the OpenSource world has given to me (I like to think about it as 'from the OpenSource to the OpenSource').

Details:

The NiCr project can be divided in three parts: Machine, Arduino and FreeCAD

-Machine:

The machine is the physical thing, and is being designed to be built from easy to find, easy to work with materials, like extruded aluminium tubes and simple bolted joints, taking into account a low budget and the DIY factor (only cut/drill/bend operations).

It features two CoreXY frames, easy-to-find Nema17 motors, and a spring tensor for the wire. The design is also very scalable and can, possibly, be applied to other type of machines.

The design has taken place between FreeCAD and the real world:

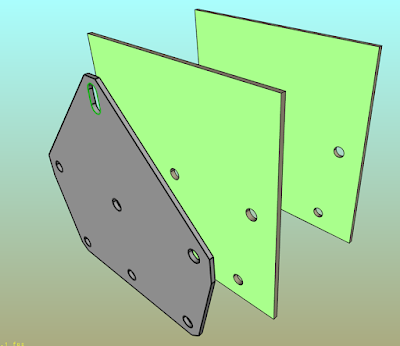

FreeCAD pictures:

|

| Detail of the Nema17 stepper, X axis slider and belt pulleys |

|

| Machine assembled inside FreeCAD |

|

| Frame size |

|

| Slider on the X axis |

|

| First version of the cut-wire tensor |

-Arduino:

The machine movement is done with an Arduino Mega 2560 board and a Ramps shield, that, together with four stepper drivers (A4988), some limit switches and a power source form all the electronics.

The firmware is being developed specifically for this machine, you can see some of its parts in this links:

-FreeCAD:

The shapes are created using FreeCAD existing tools and converted later to .nicr (similar to GCode) in a custom workbench.

This workbench features a parametric machine, a shape-to-path algorithm, trajectory planning and simulation tools.

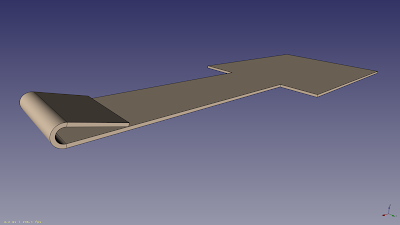

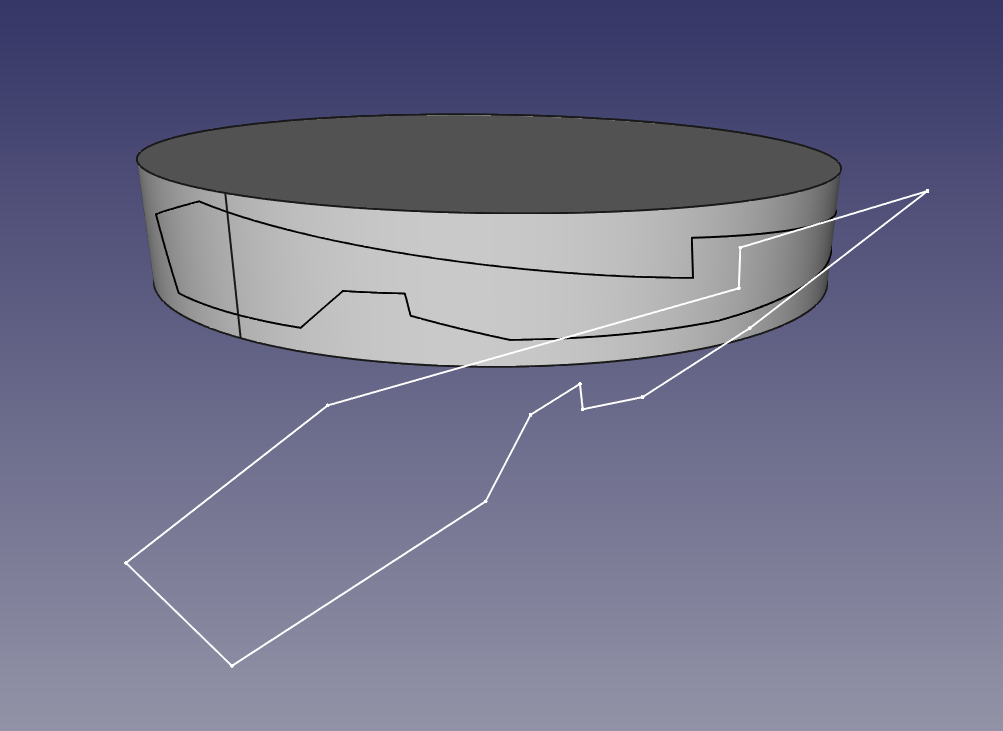

Some pictures of the workbench:

|

| Workbench and parametric machine |

|

| Cut path simulation result for three wings with different precision settings |

Workbench demo video:

Why I have not used the path workbench (in development) and the existing GCode standard?

Because this machine produces 2.5D shapes (could do '2.75D' with the addition of a fifth axis, to be studied) and the movement is very different to the movement of a 3D printer or mill, and by using 4 axis, someone can be mistaken and use the code for the wrong machine.

Anyway, it is going to be a documented language so export-import tools can be created if needed.

Conclusion:

NiCr is in active development, at the moment I'm trying to achieve a basic stability and usability of the softwareOnce I achieve that, the code and machine 3d parts will be uploaded to github

I'll be updating this post with any news I have.

-> January 1, code uploaded to github: https://github.com/JMG1/NiCr

By the way, have a happy 2016!

Javier.